Alkaline Water Electrolysis System from Hande Hydrogen

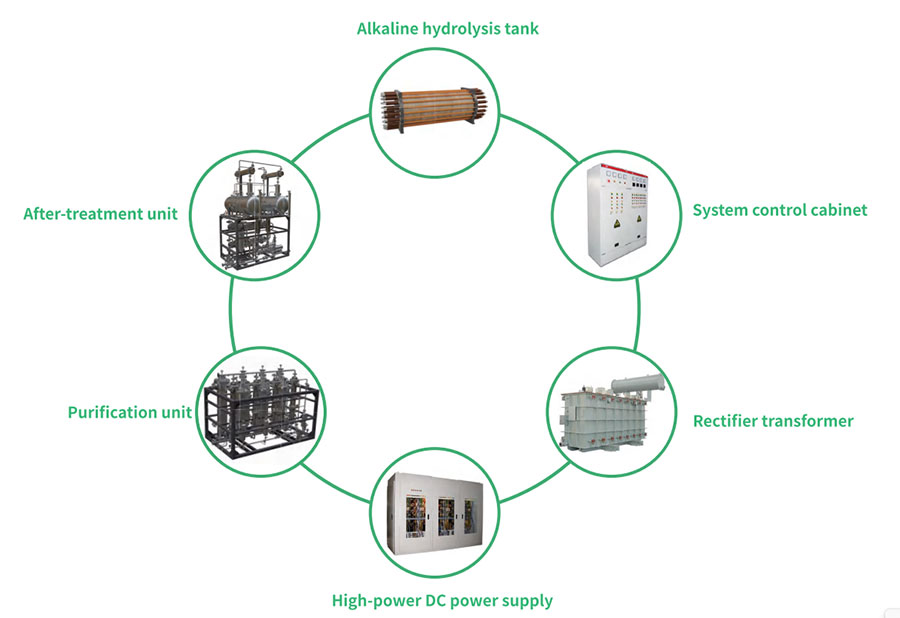

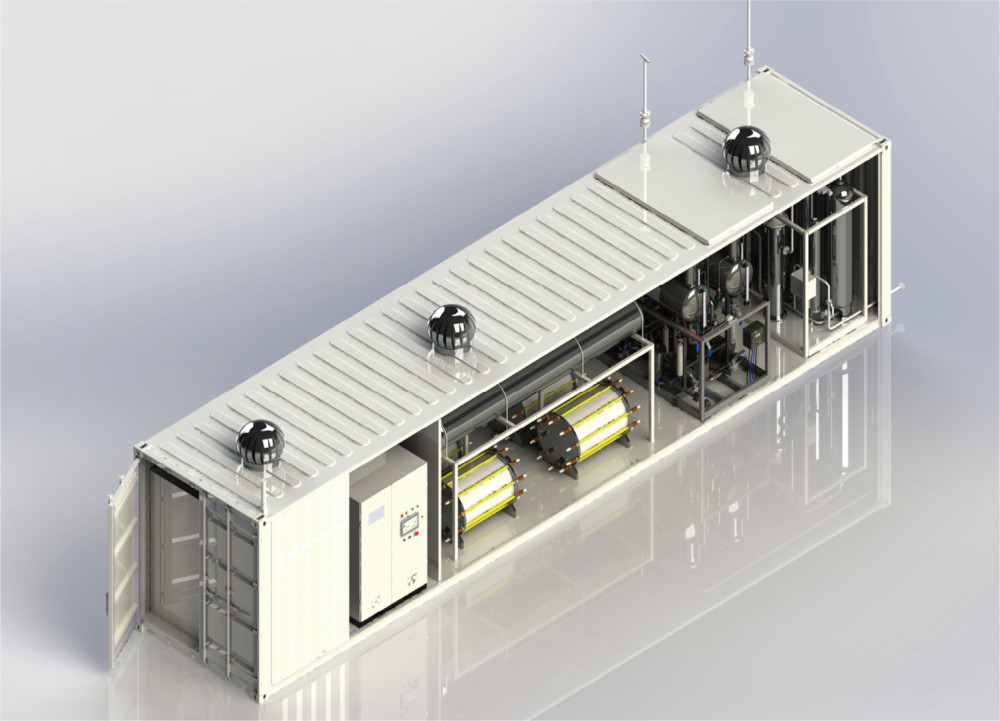

Hande boasts full industry supply capacity for alkaline water electrolysis equipment, pivotal for hydrogen production:

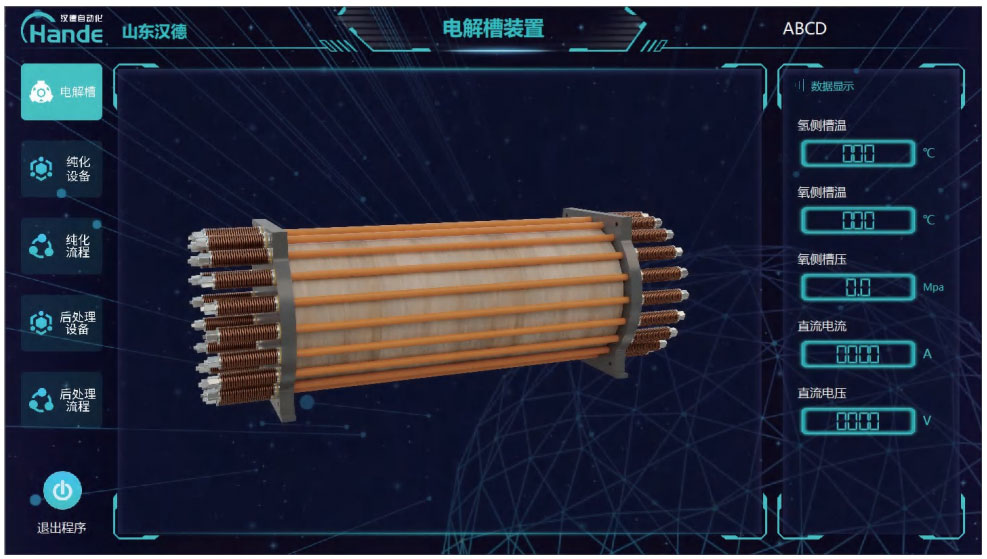

- Product lineup: Bipolar press filter alkaline hydrolysis tank, Auxiliary equipment, Electronic control equipment.

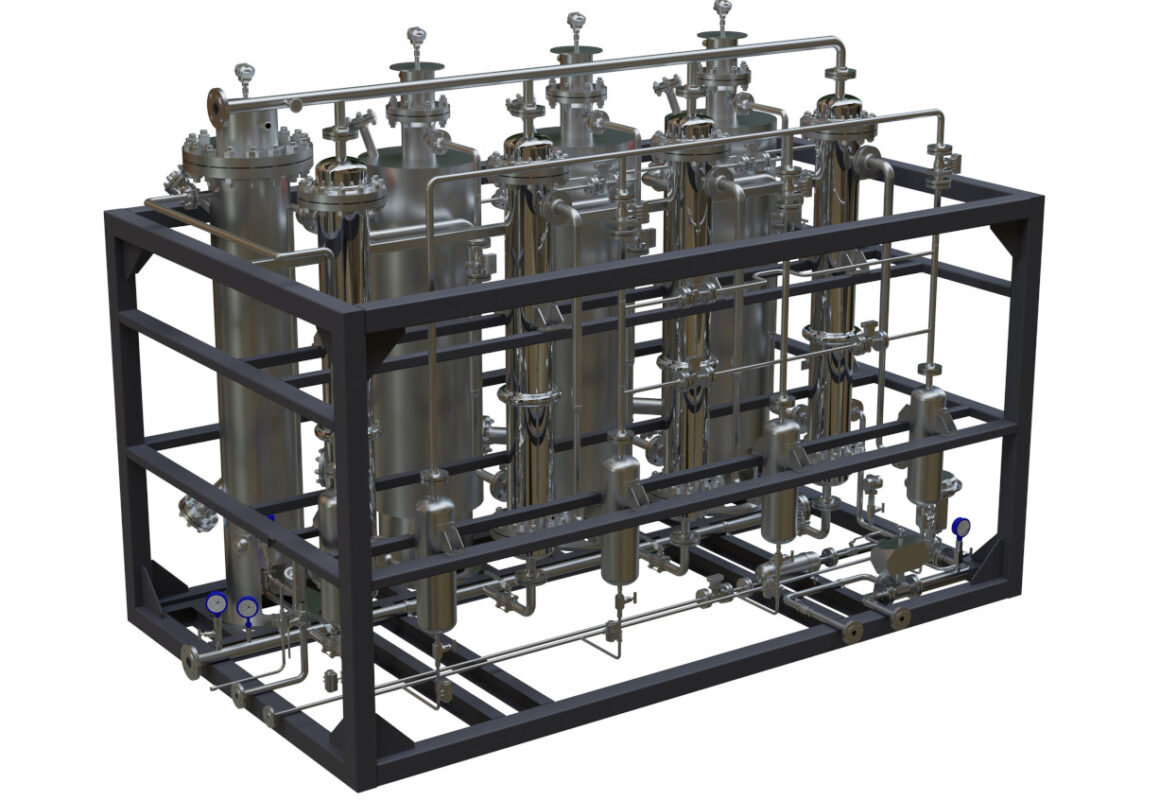

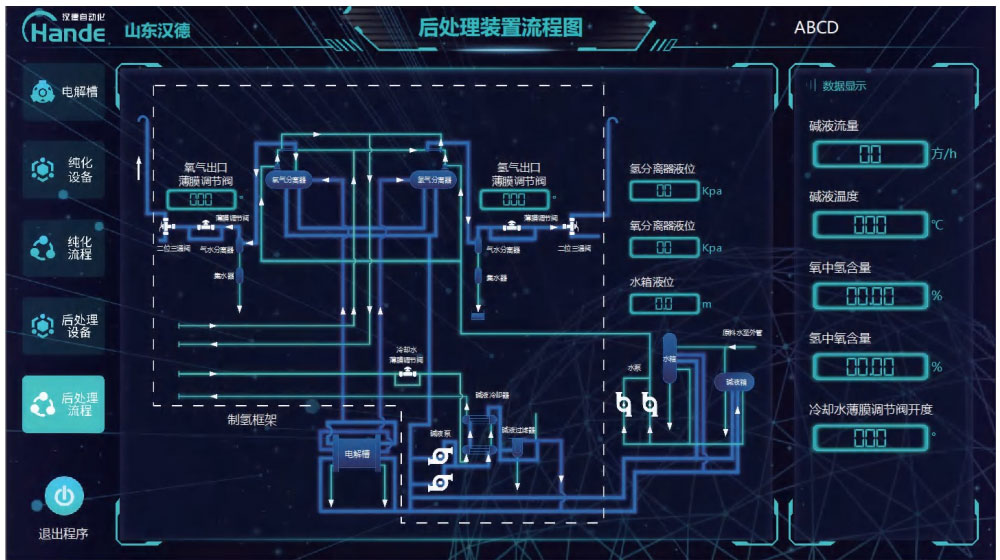

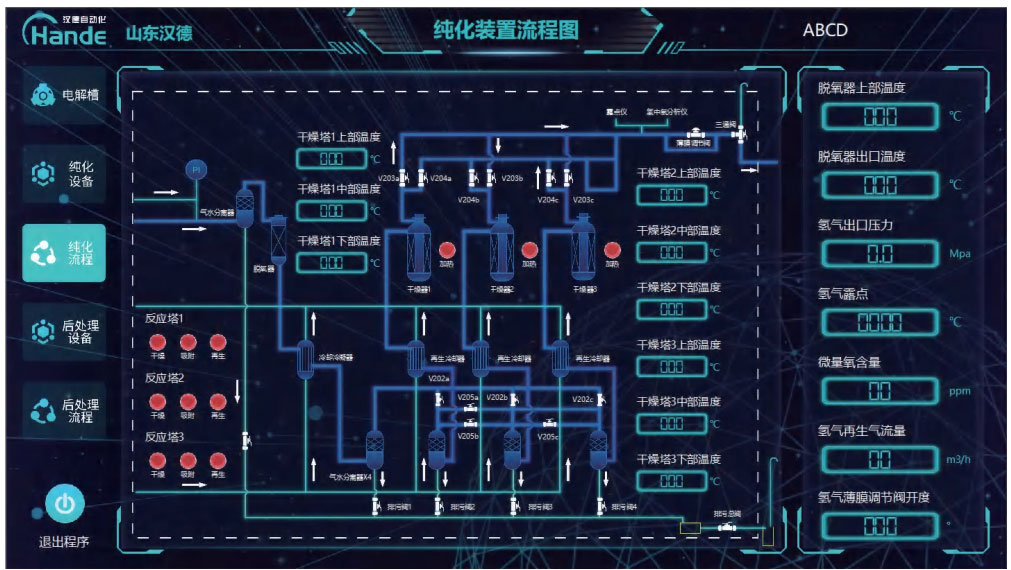

- Auxiliary equipment includes Alkali liquid tank, Water box, Alkali liquid reprocessing framework, Hydrogen purification framework.

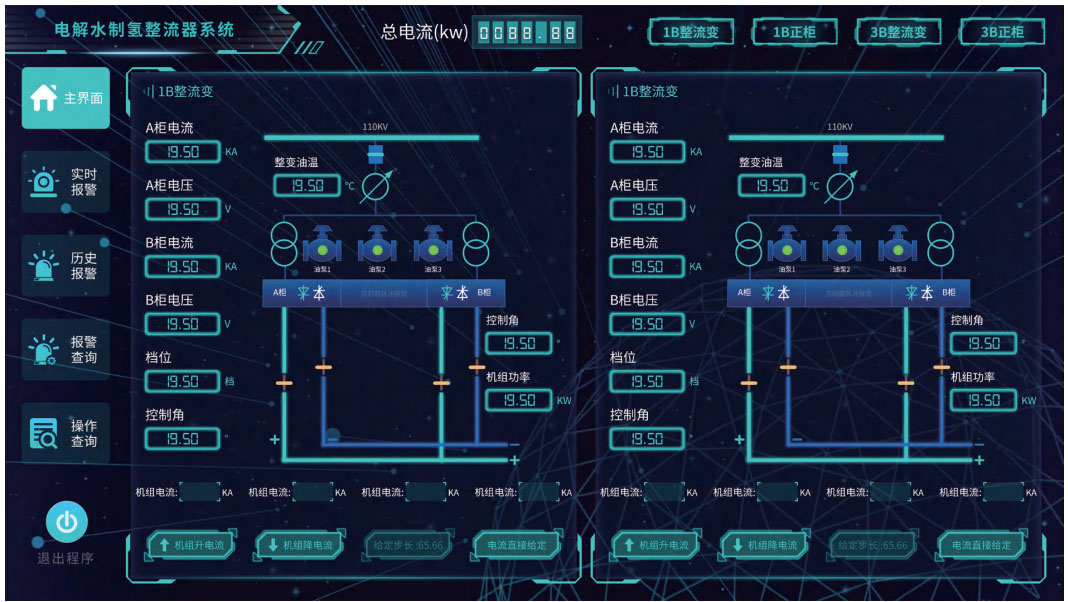

- Electronic control equipment consists of Rectifier transformer, Rectifier cabinet, Water-cooling cabinet, Rectifier control cabinet, System control cabinet.

- Features: Fast boot, compact design, 30-110% power-adjustable, low power loss, zero alkali liquid pollution.

Download Our ALK System Technical Brochure