While direct seawater electrolysis is often considered the “Holy Grail” of green hydrogen, transitioning this technology from laboratory theory to industrial application has been a major global challenge.

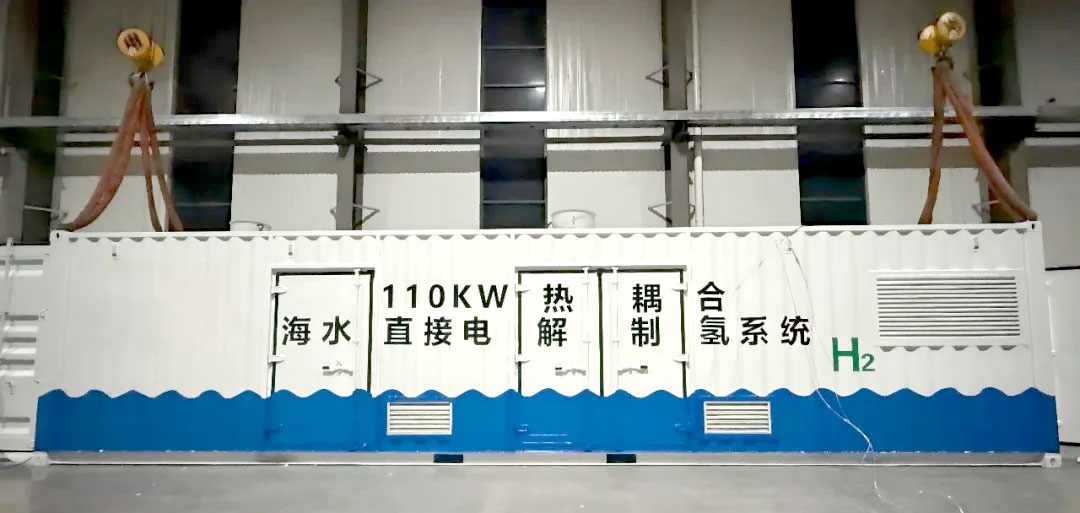

Recently, Hande Hydrogen, in collaboration with national-level laboratories, achieved a significant engineering breakthrough: the successful 500-hour continuous stable operation of China’s first 110kW thermal-coupled direct seawater electrolysis system.

The Engineering Challenge: Corrosion and Scaling Directly electrolyzing raw seawater without complex pre-treatment (like desalination) typically leads to two “fatal” issues: severe chloride corrosion and rapid electrode scaling due to magnesium and calcium deposits.

As the core engineering and system integration partner, Hande Hydrogen focused on transforming laboratory innovations into a robust industrial-grade electrolyzer:

- Advanced Material Selection: We utilized specialized corrosion-resistant materials and optimized flow-field designs to suppress chloride interference.

- Structural Optimization: By refining the electrode structures, our team successfully mitigated mineral deposition, ensuring long-term stability without the need for high-cost desalination units.

- System Integration: The system integrates waste heat recovery from industrial sources (such as steel or petrochemical plants) to optimize the electrolysis process, significantly improving overall energy efficiency.

A Scalable Path to Zero-Carbon Coastal Industry This 500-hour run proves that decentralized green hydrogen production is viable in coastal industrial zones. By capturing low-grade industrial waste heat and utilizing raw seawater, we can provide a cost-effective, zero-carbon energy source for high-emission industries.

Looking Ahead For Hande Hydrogen, this milestone is just the beginning. We are committed to bridging the gap between scientific discovery and industrial-scale deployment. By focusing on durability and cost-optimization, we continue to provide reliable electrolysis solutions for the global energy transition.