Electrolysis for hydrogen production from water is a concept widely familiar to many, especially concerning its adaptability to intermittent and fluctuating renewable energy sources, particularly in Proton Exchange Membrane (PEM) systems. However, integrating alkaline electrolysis with renewable sources remains a subject requiring further research and validation. Presently, most hydrogen production demonstration projects are still reliant on the grid or significant energy storage, lacking the comprehensive sustainability characteristic of “green hydrogen.” The following discussion serves as a springboard for contemplation.

Renewable Energy Hydrogen Production Systems and Grid Stability

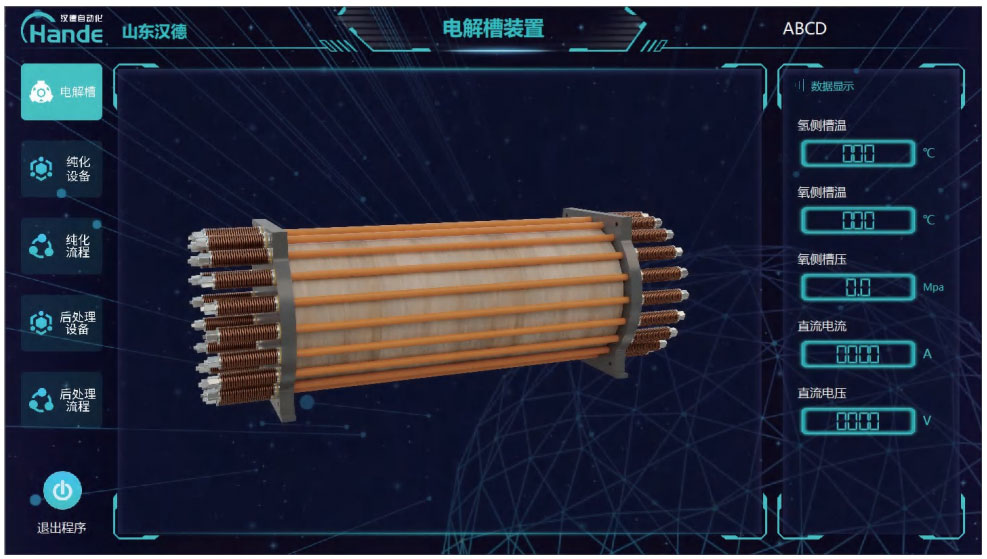

Direct hydrogen production from renewable sources typically involves photovoltaic (PV) electrolysis, wind-driven electrolysis, or a combination of wind power and electrolysis. A typical demonstration process for a hydrogen energy system integrates PV and wind turbine electricity generation connected to a direct current (DC) bus via appropriate converters (PV DC/DC, wind turbine AC/DC). This DC bus then powers the alkaline water electrolysis cells. The produced hydrogen can be stored for later use in fuel cells or other applications.

Fuel cells are also connected to the DC bus, allowing the grid to utilize the electricity generated by these fuel cells via DC/AC converters. During periods of low energy demand, hydrogen can be produced and converted back to energy when needed. Traditional alkaline water electrolysis cells are designed to operate under steady-state conditions, hence the need for additional energy storage devices (such as batteries, supercapacitors, or flywheels) to mitigate and manage fluctuations.

When surplus energy is available, these storage devices can be charged for full availability when required. However, the capacity of storage is limited by the installed equipment, thus limiting the degree of damping. Moreover, the generated hydrogen can also be used for decarbonization in industrial processes or as fuel for the transportation sector. Optimal system design, aimed at minimizing DC/DC converters, can enhance overall efficiency while reducing system flexibility. Additionally, if alkaline water electrolysis cells can operate under dynamic conditions, the need for (excessive) additional energy storage devices may be reduced or even eliminated. However, before this possibility can be realized, electrolysis cells (electrolysis systems) must overcome several challenges.

Renewable Energy Integration and Grid Stability

Renewable energy sources, such as PV and wind turbines, power alkaline water electrolysis cells, while stored hydrogen can be converted back to electricity through fuel cells. Consequently, oxygen or air can be utilized (with a portion of oxygen potentially being fed into fuel cells to enhance reaction efficiency). Additional energy storage devices can mitigate and manage fluctuations, making the entire hydrogen energy system viable for stabilizing the grid.

As the proportion of renewable energy in the grid increases, maintaining a constant power frequency becomes crucial. This hydrogen energy system or alkaline water electrolysis cells can stabilize grid frequency by dampening fluctuations. Another benefit is the reduction of traditional spinning reserves, thereby lowering costs and carbon dioxide emissions. Predictive control can be employed to achieve stable and efficient operation. Pressurized alkaline electrolysis cells are more suitable for suppressing rapid fluctuations, while atmospheric pressure devices can handle slower fluctuations.

Limitations and Solutions

Implementing hydrogen energy systems in existing grids is a challenging task that requires overcoming some limitations to ensure high availability. A major issue with alkaline water electrolysis cells powered by renewable energy within a partial load range is the high gas impurities (hydrogen in oxygen), which can lead to shutdowns due to safety concerns when external gas impurities reach 2 vol.%. Therefore, the operating time of electrolysis equipment is limited to periods when renewable energy generation is sufficient.

Limited operating time results in numerous startup and shutdown cycles, potentially exceeding the maximum startup/shutdown cycles specified by electrolysis cell manufacturers, thereby reducing the expected system lifespan or warranty agreements. Electrodes are primarily affected by repetitive startup/shutdown actions, accelerating their degradation. It is widely known that nickel electrodes degrade significantly after 5000 to 10,000 startup/shutdown cycles. If only photovoltaic generation is used, this cycle can be reached within 20 to 30 years, totaling 7000 to 11000 cycles.

The fluctuating nature of renewable energy exacerbates electrode degradation, as this phenomenon (fluctuation) is somewhat similar to a startup/shutdown process, a problem that can be addressed by developing stable electrode compositions or self-healing electrode surfaces. To mitigate the drawbacks of relying solely on one renewable energy source, such as limited operation during solar generation only during daylight hours, combining several energy sources can enhance overall efficiency. The Faraday efficiency of using only photovoltaic generation is approximately 40%, whereas wind power generation’s Faraday efficiency is about 80%.

The combination of both technologies increases the Faraday efficiency to over 85%. To prevent gas impurities (purity) from reaching the explosion limit (2 vol.%), the partial load range of most alkaline electrolysis cells is restricted to 10% to 25% of their nominal load. Fluctuations below the minimum load can be balanced by using energy storage devices; however, in some cases, the available energy storage devices may not be sufficient. When gas impurities remain within tolerable limits, short-term electrode polarization may be allowed. Significant decay begins when the cathode voltage drops below approximately 0.25 V. Therefore, complete shutdown can be maintained until this voltage limit is reached. The available time depends on the electrode composition, as the electrochemical double layer acts as a capacitor, delaying voltage breakdown after shutdown. Experimental reports suggest a time span of approximately 10 minutes.

Optimal System Design and Operational Strategies

To alleviate gas impurities during low power (load) availability periods, optimal system design should allow enough time until sufficient energy is available again. The gas volume within the system can act as a buffer tank, diluting gas impurities, while the liquid and solid volumes of the electrolysis cell can buffer system temperature during partial load operation.

Furthermore, to maintain high efficiency, the system temperature must be within the optimal range of 50 to 80°C for an electrolyte solution containing 20 to 30 t.% KOH. Since most alkaline water electrolysis cells powered by renewable energy sources do not provide separate heating units (additional electrolyte heating units to maintain alkaline temperature), temperature is achieved and maintained solely through reaction heat. A suitable cooling system should be employed to prevent temperatures from exceeding 80 degrees Celsius (or slightly higher) to avoid high degradation rates (accelerated degradation at high temperatures). Another approach is to operate at lower temperatures to suppress electrode degradation, but this requires highly active electrocatalysts to achieve sufficient efficiency.

To gain a comprehensive understanding of the dynamic behavior of alkaline water electrolysis cells powered by renewable energy sources, further experimental and theoretical work is required. Apart from optimizing system design, appropriate dynamic operating strategies also aid in reducing gas impurities. Separate electrolyte circulation generates low gas impurities, while combined modes generate high gas impurities.

When electrolysis cells can automatically switch between the two operating modes, they can switch to separate mode when gas impurities are too high, then switch back to combined mode when there is sufficient gas production. Experimental results indicate that through this approach, gas impurities (hydrogen in oxygen) can be reduced by almost half.

Gas (impurity) contamination primarily occurs during continuous operation at low current densities (low load). To avoid this situation, the total electrode area of the cell can be reduced (overloading), or the system can be subdivided into several smaller sections. While smaller electrode area electrolysis cells limit maximum loads compared to larger systems, partial system operation is a more appropriate approach. In cases of inadequate power supply, individual electrolysis cells or sections of systems with multiple cells can be powered off, reducing the available electrode area to achieve higher current densities. However, this strategy may encounter issues in maintaining optimal system temperature due to component disablement. Another method to prevent adverse engineering states is through the use of predictive control systems. For example, when low availability of renewable energy is predicted, the system can change temperature, pressure, or operating mode to a more suitable state before negative impacts occur.

Conclusion

The integration of alkaline water electrolysis with renewable energy sources for sustainable hydrogen production is a crucial step towards decarbonizing industrial processes and the transportation sector. To identify the most relevant limitations and propose appropriate solutions, a comprehensive understanding of the relevant technologies is essential. Alkaline water electrolysis processes can be determined by current-voltage characteristics and gas impurities produced, while PV and wind turbines should operate at their maximum power points.

Various modeling approaches currently exist, and the most suitable one should be chosen. Although empirical correlations typically apply to specific experimental setups, physically reasonable models can be more universally applied to develop new solutions. For alkaline water electrolysis, numerous experimental and theoretical data are available for calculating and analyzing battery voltage under operating conditions. As each electrolysis cell’s actual system design and cell arrangement differ, certain parameters must be determined through experimentation to apply proposed models to another system. This issue primarily exists in electrode composition and membrane materials. Describing the gas purity of hydrogen and oxygen using mathematical methods faces challenges due to numerous influencing variables, currently only empirical models and correlations are available. Since gas impurities are the primary factor determining alkaline water electrolysis cell system availability, further research is needed to develop physics-based models. Dynamic system behavior analysis is necessary as optimized dynamic operating strategies contribute to increasing overall system efficiency.

Currently, various models of varying complexity are available to describe the current-voltage characteristics of photovoltaics. Most models rely on physical principles and manufacturer data. Therefore, appropriate coefficients can be established for different systems. Wind turbine power conversion can be described by appropriate correlations between system characteristics and performance coefficients. Since this variable is influenced by many parameters, including wind turbine blade design, the correlation can only be used for very similar wind turbines or must be determined through experimentation or simulation.

In conclusion, appropriate models exist for all components of hydrogen energy systems. However, some descriptions need further improvement to be applicable to various system designs. With this knowledge and experimental research, many researchers have already studied the limitations of alkaline water electrolysis cells powered by renewable energy sources. The core prospect is to extend operating time through intelligent system design and favorable operational concepts. While employing traditional energy storage devices to balance and stabilize power is a reasonable initial step, alkaline water electrolysis cells should be able to directly handle all power, reducing costs and improving efficiency.